The life of a diamond cutter can be a stressful one. After all, the cut is the one quality factor that can make or break the overall appearance of a diamond. It can help hide inclusions while also bringing out the maximum amount of brilliance. Diamond cutting is a very work intensive process and must be done with the utmost precision in order to achieve excellent polish and symmetry. So how exactly does the magical transformation of rough diamonds into gem-quality ideal cut diamonds happen?

Well first, a hopeful diamond cutter needs to learn the ins and outs of the diamond cutting process. Schools that offer diamond cutting programs include the American Institute of Diamond Cutting and the Corlia Roberts Diamond Education College. Depending on the program, learning how to accurately cut a diamond can take anywhere from three to six months and at least a few thousand dollars.

Once a diamond cutter has learned all of the necessary steps required in this skilled craft, they can begin to cut diamonds professionally.

The first step in the diamond cutting process is analyzing the rough gem and planning the most ideal cuts. With the help of a sophisticated computer, diamond cutters are able to determine which shapes are most ideal for a particular rough diamond and then create a plan to minimize potential waste and maximize brilliance.

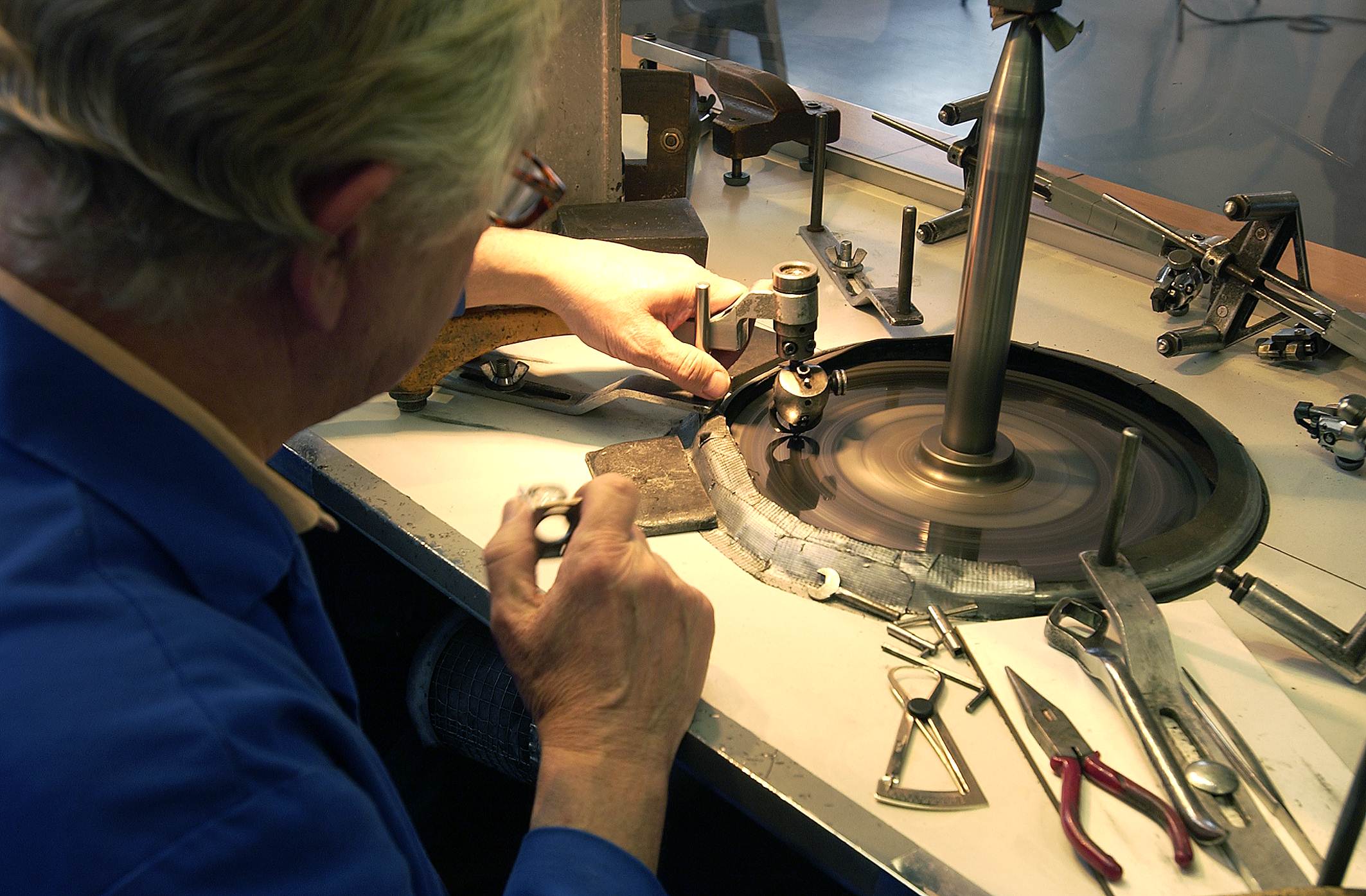

After all of the planning, the diamond cutting process can begin. If the diamond is large enough, it will be cut into several pieces, each of which will become their own gemstone. If the diamond will end up being a round cut diamond, the diamond cutter will place two diamonds on a spinning axle and force them to rub up against one another until both diamonds have a round shape. As you may know, diamonds are the world’s hardest materials, so only another diamond or a laser can cut them. Because of this, diamonds are commonly cut on a rotating turntable covered in an abrasive diamond powder that slowly polishes away the material. Another tool commonly used during the diamond cutting process is an angle gauge, which helps the diamond cutter make proper cuts at the correct angle.

The diamond cutting process is an exhaustive one. It often takes several people to cut just one diamond. Often times, one diamond cutter will make the initial cuts to create a template for the next stage of the process. Then another diamond cutter, often called the brillianteer will add the remaining facets in order to maximize brilliance. There is usually one other person who then inspects the diamond and determines if the cut is acceptable or needs more work.

After the diamond has passed quality inspections, it is sent to gemological labs who will then grade the diamond based on its color, cut, clarity, and carat weight.

So now you have a better understanding of all the work that goes into creating the magnificent diamonds you see worn in jewelry every day. Hopefully next time you look at a diamond, you’ll appreciate their beauty a little bit more.